Thermoformed Fiber Packaging

Our thermoformed pulp products are manufactured in clean, hygiene, certified food-contact safe factory where our food-service items are also manufactured

- Excellent vibration and shock resistance properties

- Low tooling costs are typically less than other packaging materials, such as thermo & vacuum formed plastics

- Static Free: Molded pulp is chemically and electrically neutral

- Soft Surfaces: No scratching or unwanted abrasion

- Climate Tolerance: Our products perform in virtually all temperatures and humidity

Applications:

Consumer Electronics Packaging; Beverage Secondary Packaging; Container Primary Packaging; Disposable Medical Products

Molded Pulp Packaging Solutions

Molded pulp, also referred to as molded paper pulp or molded fiber, is made of 100% non-tree based fiber such as wheat straw , sugarcane, etc.. They are the remaining plant material after the wheat grain and chaff have been extracted from the plant and then we turn these agricultural wastes into renewable packaging materials.

| Materials | Molded Fiber | Corrugated Box | Styrofoam EPS Foam | Tote |

| Price | Low | Medium | High | High |

| Recyclable | Yes | N/A | No | Varies |

| Bio-Degradable | Yes | N/A | No | No |

| Nestable | Yes | No | No | No |

| Assembly Required | No | Yes | No | Yes |

Molded Fiber vs. Other Packaging Options

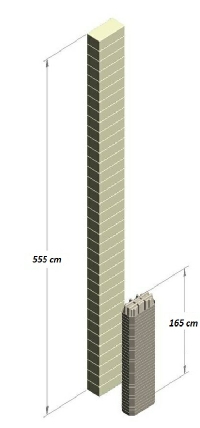

50 nested Molded Pulp endcaps 65.3″ high vs.50 EPS endcaps 218.75″ high = 70% warehouse space saved with Molded Pulp

| Material | Molded Fiber | EPS Foam |

| Sustainability | Recyclable, biodegradable & compostable | Non-biodegradable |